|

||||||||||

|

NEWS from HENOR AS:

January 2011:

Sucessful sales and delivery of a new Kellenberger 1000 U universal grinder tol the Norwegian Air Force workshop at Kjeller.

March 2009:

A most successful delivery of the ELB machine, with excellent grinding capacity - both on profiling and normal surface grinding. Much thanks to a very stable and capable machine.

December 2008:

Order for an ELB Smart BD10 STC full enclosure profiling and surface grinding machine to North Cape Minerals AS to be supplied within March 2009.

Trial order for a Kelch Kalimat C34 to Frank Mohn Fusa A/S. Apart from presetting, the emphesize is on communication with 2 DMG machining centres with Balluff / Siemens 840, where there has been severe problems up till now.

July 2008:

We participate in Booth D08-18 at Den Tekniske Messe 22 - 25 September at Lillestrøm.

We will be exhibiting - among other products - a KELCH Kalimat C presetter, and we are happy to invite our customers to visit us.

`June 2008:

Sales of a second -hand Kellenberger to Sliping & Honing AS, a 1000 R hydraulic machine.

May 2008:

Another Kellenberger grinding machine KEL-VISTA UR 175 x 1000 order achieved! This one to Mandals Technology AS (the former reperbane), with delivery in October 2008

November 2007:

The first order to Slipeservice ANS for a KELCH Kalimat A/S CNC presetter with 2 cameras, automatic measuring cycles, 2 screens for projection and surface analysis. System to be suplied January 2008

September 2007:

Order for another Kellenberger KEL-VISTA UR 175 x 1000 / Fanuc 21i to Raufoss Industrial Tools AS, with delivery August 2008. This is the second Kellenberger machine they procure.

February 2007

Sales of a Kellenberger 1500 U heavy-duty to Trio AF Teknikk AS from the Norwegian bank, delivery March 2007.

December 2006:

The first order for KELLENBERGER´´s latest KEL-VISTA, 2-axis CNC cylindrical grinding machine. Fusa Mek. Industri AS opted for the KEL-VISTA among several others. The machine will be supplied in June with full installation and training and norwegian operating manuals.

June 2006:

Important order for a large crankshaft and roll grinding machine from VERECO to customer in Bergen, complete supply will be in January 2007. The machine handles Ø 1.150 x 5000 mm, with weights up to 4 metric tons and crankshaft eccentricity up to 240 mm.

March 2006:

A major combined STREULI magnetic and paper filtration system supplied to Pratt & Whitney Norway Engine centre for simultaneous filtration of coolant from 2 vertical turning machines.

September 2005:

EMO 2005 in Hannover gave interesting new enquiries and important new contacts both among customer as among suppliers.

2 well-sized filtration systems supplied to Electrolux Motor and to LFK (norwegian airforce), the latter handling to machines simultaneously. Both installations sucessfully installed.

December 2004:

A series of diamond and CBN wheels from Triefus-ADIE sucessfully supplied to customer confirms the quality and competitiveness of this manufacturer.

October 2004:

2 major orders for Triefus A.D.I.E. SA large size diamond wheels to customers in Norway represent the break-through for this manufacturer. Wheel sizes are Ø 610 x 40 mm and Ø 750 x 40 mm each.

A very interesting order for a SUPFINA 204 superfinish grinding attachment , to be supplied to Norske Skogindustrier ASA - Sugbrugs for grinding away spiral traces on their rolls.

Added to this - for the same customer - also an special order for a stainless steel brush of Ø 700 x 80 mm for degrading perforated rolls. The brush will be set up in the roll grinding machine, like a grinding wheel.

September 2004:

We took part in the Technical Fair in Oslo 21 - 24. September. A well worth experience with interesting inquiries and orders during the show.

January 2003:

A FAVRETTO automatic Profile- and surface grinding machine type MB-100 AUTO DGT is supplied to TRITEC AS. The machine is to grind heavy formtools, having a requirement for stability, high precision and fast cycle times. The machine has a spindle capacity of 11 kW for wheel of 400 x 100 mm with automatic operation, including 12 automatic profile dressing cycles. It replaces 3 old surface grinding machines and still offering added capacity.

December 2002:

Slipeservice ANS order a second tool grinding machine! The the brand new Michael Deckel S22P, a 5-axis tool grinding machine to be delivered in April 2003, following the successful supply of a S20P in 2001. It demonstrates a clear and dedicated effot to be a major supplier as well a a high degree of success in CNC tool grinding. The two machines are both fitted with the Michael Deckel Turbo CNC-control which won a 1.prize at IMTS in Chicago for user friendliness. The machine is extremely fast and accurate, has a direct AC-spindle drive for 3.000 - 8.000 r.p.m, handles pick-up loader or tool magasion (max. 2 x 240 pcs.) and shafts up to Ø32 mm. There is a tool magasin for 24 wheels (8 sets each of 3 wheels with max. Ø 150 mm).

August 2002:

A large TUREX heavy duty wheel storage system type SSAS 900/5 installed at Hydro Aluminium Roll Mill at Karmøy, handling large and heavy wheels of Ø 915 x 100 mm with a weight of 265 kg each! A special hydro-mechanical clamping system allows for absolute safety in handling the wheels by lift-up fork, from the TUREX cabinet on to the machine spindle without risk of operator injury.

May 2002:

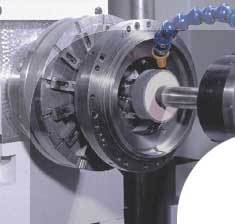

Henor as is supplying a Kellenberger 2R 175 x 1000 mm for high production grinding of ceramic sleeves with a diagonal grinding head allowing for both a coarse and a fine wheel. The sleeve is ground on both faces, 15 degree angles on either end as well as cylidrical surface - all in one single operation. The customer Frank Mon Fusa A/S already has a KEL-VARIA for shaft grinding supplied in 1997, as well as 2 older 600 U machines.

April 2002:

The most advanced cylindrical grinding machine in Norway - a Kellenberger KEL-VARIA UR 175 x 1000 mm with a 4-axis Kelco 120 CNC control - supplied to the well- kown company TEENESS ASA for grinding precision boring bars, high precision complex tooling, as well as thread grinding and non-round profiles, straight and at angles.

November 2001:

Another Michael Deckel S20P Turbo 5-axis tool grinding machine, delivered to Forus Industri AS - Dept. Precision grinding. This machine will be used for resharpening as well as grinding of new tools, with the interesting addition of offering new technology in tool grinding when training people for relocated jobs.

August 2001:

An S20P Turbo 5-axis tool grinding machine from Michael Deckel is supplied to Slipeservice ANS, Kongsberg in their process of reclaiming from foreign suppliers an interesting market for resharpening of tools and new tools grinding, and offering services to the near by Kongsberg Industrial Park (with defence and aerospace manufacturing facilities).

September 2000:

The first high capacity wheel storage system from TUREX GmbH supplied to Hydro Aluminium Roll Mill in Holmestrand as part of their emphesize on HMS (operator safety). The SSA 750/6 Cabinet system accomodates 6 wheels each of Ø 750 x 80 mm, to be handled by lift-up forkes.

Olav Brunborgsvei 27, N-1396 Billingstad, tlf. 66 85 93 94 - fax. 66 85 93 95 - henor@henor.no - www.henor.no